Vessel

.

.

.

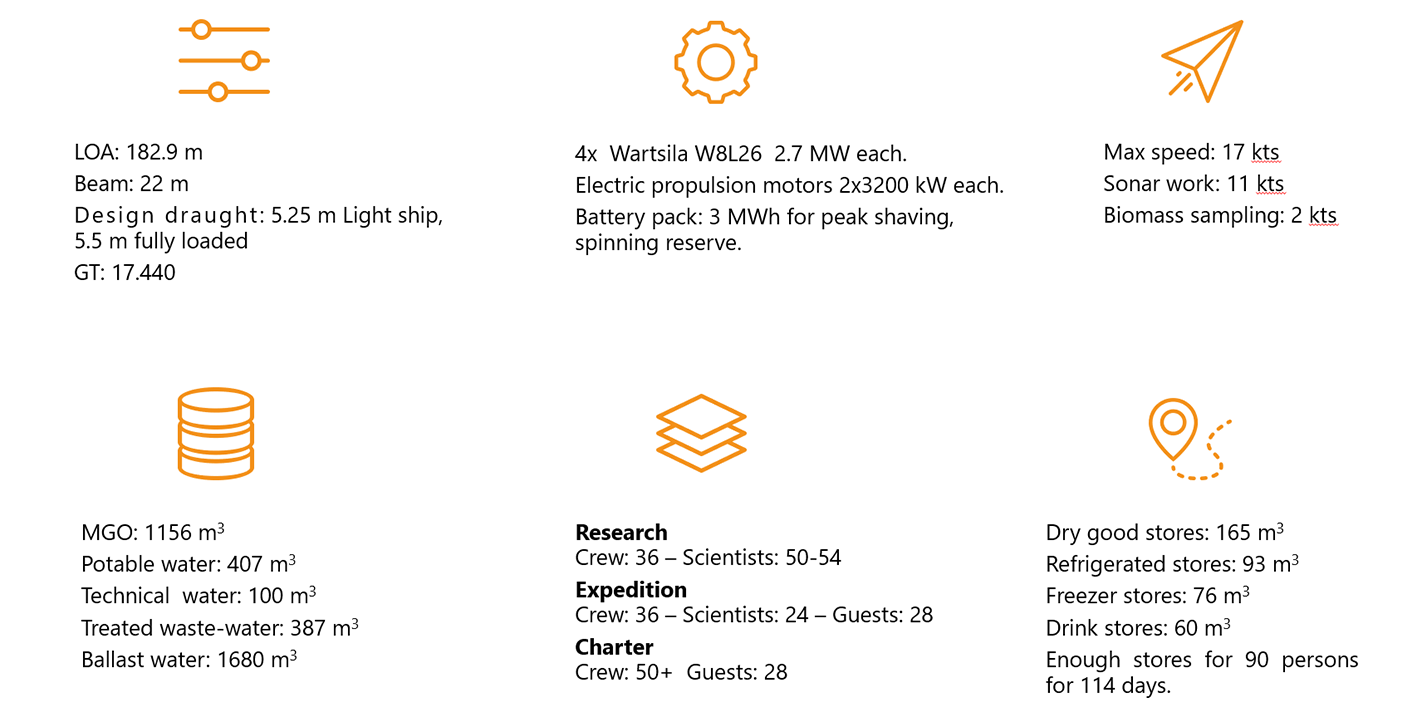

The REV Ocean vessel has several unique attributes including its extended range and endurance. This will allow the REV Ocean vessel to operate globally with the exception of areas with heavy sea ice, where an icebreaker would be needed to accompany the ship. The REV Ocean vessel will operate in 3 modes: Research, Expedition and Charter.

Specifications

Class

DNV-GL 1A1, Passenger Ship, E0, ICE 1C, NAUT-NAV, BIS, CLEAN DESIGN Tier III, BWM-T, Recyclable, HELDK-SHF, SILENT-R, TMON, Battery power.

SrTP – (Safe Return to Port) x2 engine rooms, x2 switchboard rooms, x2 propulsion room, emergency bridge, emergency galley, x2 fixed fire fighting system.

USPH – (United States Public Health) galley arrangement meets US stringent health requirements for food hygiene, food transportation and handling.

Green Technology

Diesel electric engines with an additional 3 MW lithium-ion battery pack for peak shaving and ensuring optimum efficiency, with silent running under batteries alone for limited periods of time at biomass sampling speeds 2 kts during research missions.

Medium speed generators compiling with the latest Marpol Tier III regulation with additional DPF (Diesel Particulate Filters).

High efficiency frequency controlled research winch package with energy recovery system, so that power can be harvested on winch release and re-directed into battery pack.

Heat recovery on all main generators and incinerator for feeding back into hot water circuits and HVAC, reducing power demands from generators. Heat recovery system used for generating free fresh water through evaporator plant 30 m3/24 hrs.

“Free cool” system for air conditioning system in sea water temperature below 10 degrees, reducing power consumption.

Hi-tech incinerator system allowing materials onboard to be incinerated in an environmental way without producing noxious gases and creating limited char, meaning the ship does not have to offload plastic waste to shoreside facilities in countries with limited ability to dispose of plastics.

LED lighting systems throughout the vessel to reduce power consumption.

VARD SeaQ “Green Pilot” system for monitoring COx, SOx and NOx emissions plus other environmental parameters to allow the crew to run the ship in the most environmental way keeping the carbon footprint to a minimum.

Ballast water treatment system to prevent species cross-contamination across ocean zones.

Built under DNV-GL SILENT-R notation for maximum prevention of underwater acoustic pollution.

Hull construction built to ICE PC6 for navigation in ice-covered water, medium first-year ice with old inclusions, machinery specified to ICE 1C.